Dry Lubes

Mobacc dry lubes are oil and silicon-free lubricants that give a non-tacky, dry lubricating coating. Dry lubricant coatings can be used for a very wide range of industrial and automotive applications. The products are based on graphite, molybdenum disulfide or PTFE.

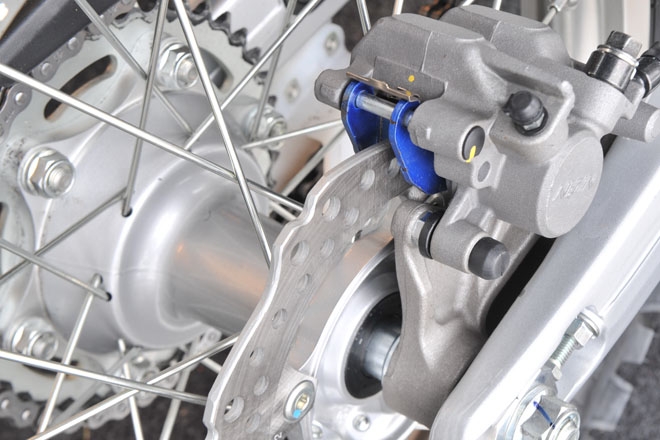

Dry lube MoS2 coating Based on molybdenum disulphide, thermoplastic resin and solvents. The product has excellent adhesion, high lubricity and extreme pressure properties. Dry Lubricant + MOS2 can be used for lubricating gears, spliced shafts, pivot pins, cams, pistons, screw jacks, toggle joints, journal bearings, coin mechanisms and hinges. Press fitting lubricant for bushes, liners and shafts. Long service life lubricant for textile machinery, vending machines, parking meters, etc., in many cases providing maintenance-free lubrication over the lifespan of the mechanism.

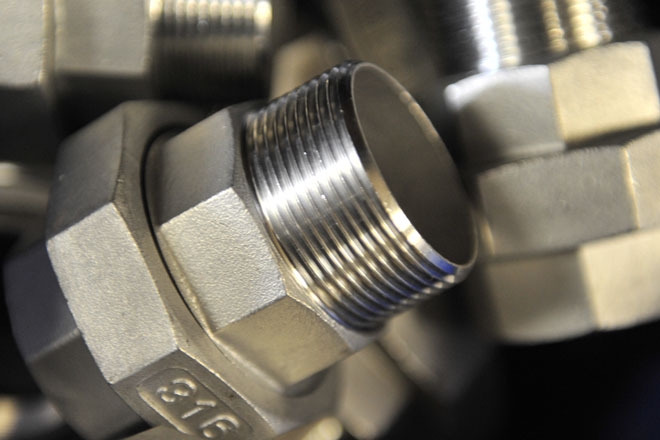

Dry lube Graphite coating A colloidal graphite bonded coating in thermoplastic resin. This coating acts as a dry lubricant that offers clean, long-wearing lubrication without redesign of component dimensions. It requires minimum surface preparation and air dries rapidly at room temperature. The product is suitable for anti-seize applications and imparts high lubricity and excellent adhesion. The product requires minimum pretreatment and cures rapidly at room temperature. Suitable for components (assembly and break-in), industrial gaskets, rubber components (assembly and break-in), thread lubricant (anti-seize).

Dry lube PTFE coating A PTFE based coating that acts as a dry lubricant, preventing accumulation of dust and dirt. PTFE has an extremely low friction coefficient and thus imparts high lubricity and excellent non-stick properties. Lubricates leather, plastics, and elastomers for use in drive belts, gaskets, packings, gears, bearings and sleeves, and chain drives. PTFE dry film coatings improve abrasion resistance, extending the lifespan of the product. They also provide dry lubrication for plastic and metallic bearing applications.